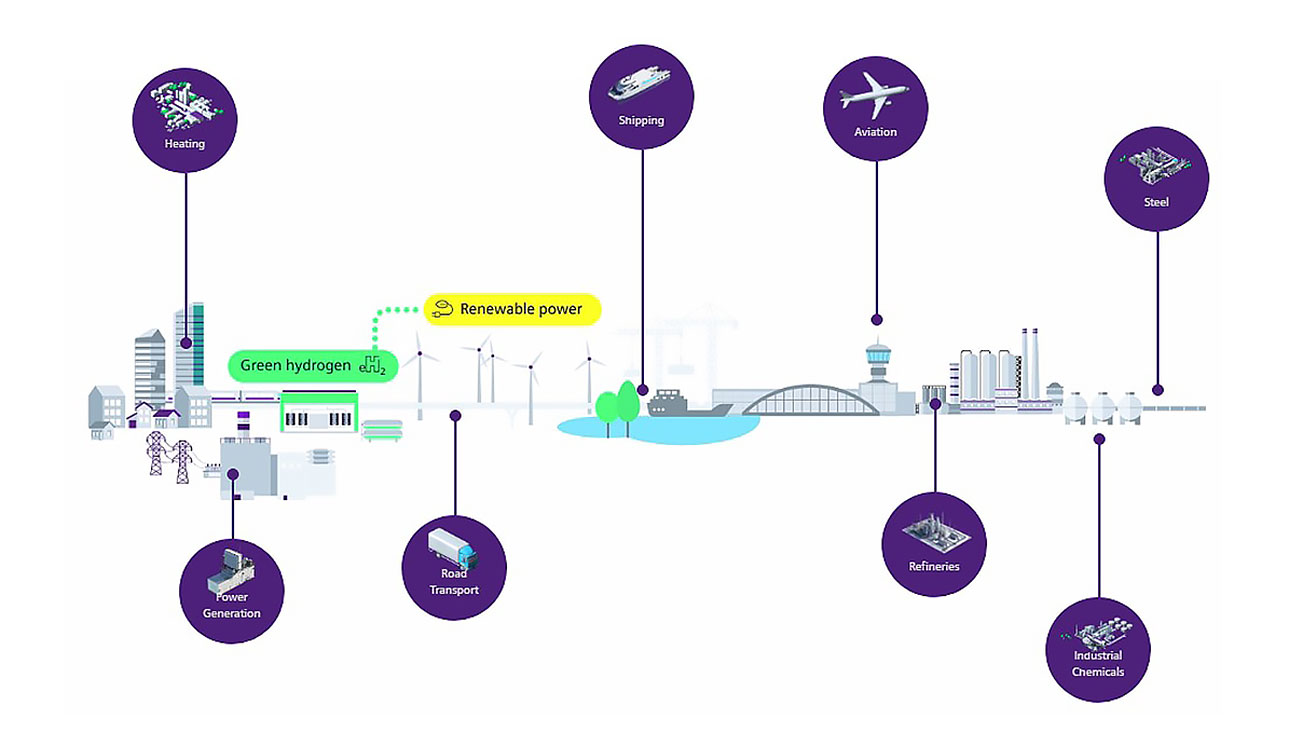

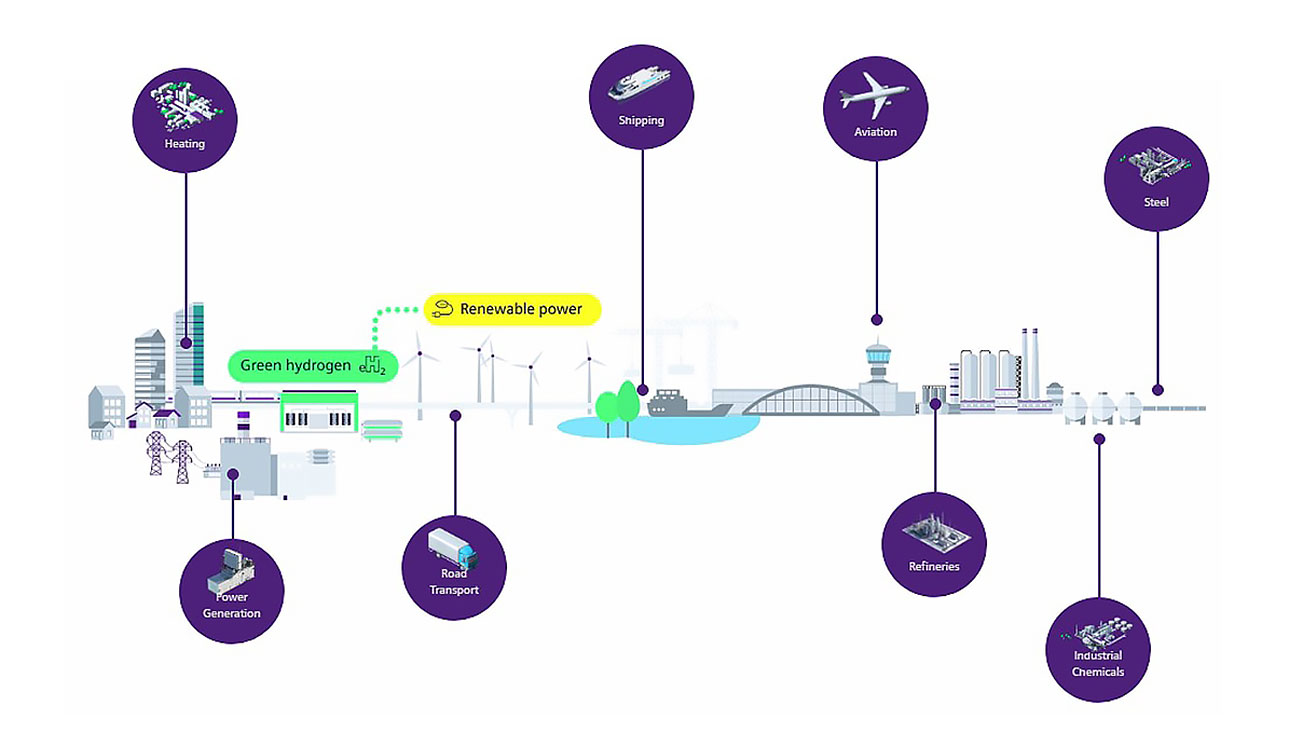

GREEN HYDROGEN HAS MANY USES

Green hydrogen (H2) is a versatile energy carrier that can be applied to decarbonize a wide range of sectors. It can be used directly or in the form of its derivatives like methanol, ammonia, or eFuels to replace fossil fuels like coal or gas.

Only around 30% of global carbon dioxide (CO2) emissions originate from power generation which can be decarbonized via electrification.

The other 70% of CO2 emissions originate from transport, industry, buildings, and others.

Hydrogen Production Using PEM Electrolysis and Hybrid Turbines

Hydrogen, touted as a key player in the transition to a sustainable energy future, can be produced through Proton Exchange Membrane (PEM) electrolysis. This process involves splitting water into hydrogen and oxygen using electricity. When paired with seawater as a source, the water must first undergo desalination to remove salts and impurities, ensuring the purity required for efficient PEM operation.

Water and Energy Demands for Hydrogen Production

Producing hydrogen via PEM electrolysis is energy-intensive, requiring substantial amounts of both water and electricity. To produce 1 kilogram of hydrogen, approximately 9 liters of pure water and significant electrical input are needed. Meeting these requirements sustainably is critical, especially when using seawater as the source.

Hybrid Mobile Turbines: A Flexible Energy Solution

Hybrid mobile turbines offer a practical solution to power hydrogen production. These turbines can operate on a mix of natural gas and hydrogen or run entirely on 100% hydrogen, making them adaptable to the evolving energy landscape. Key benefits include:

Flexibility: They can adjust fuel sources depending on availability and environmental considerations, transitioning seamlessly from natural gas to hydrogen.

Scalability: Mobile turbines can be deployed rapidly to areas with high energy demand or near desalination and electrolysis facilities.

Efficiency: Utilizing advanced turbine technology ensures high energy conversion rates, reducing waste and optimizing the hydrogen production process.

Integrating Water Desalination and Hydrogen Production

By colocating desalination plants and PEM electrolyzers near hybrid turbine installations, we can create an integrated, self-sustaining system:

- Desalination plants purify seawater, supplying clean water to the PEM systems.

- Turbines generate the electricity required for both desalination and electrolysis processes.

- The system can operate with minimal carbon footprint, especially when fueled by hydrogen or renewable energy sources.

The Path Forward

Combining hybrid turbine technology with PEM electrolysis and seawater desalination represents a robust pathway for hydrogen production. This integrated approach not only addresses water and energy demands but also paves the way for hydrogen to serve as a clean energy carrier for transportation, industrial applications, and power generation. Investing in this infrastructure today can ensure a sustainable and resilient energy future for tomorrow.

Dual Benefits of Desalination: Supporting Hydrogen Production and Community Needs

Desalination, the process of converting seawater into fresh water, is essential for producing hydrogen through Proton Exchange Membrane (PEM) electrolysis. However, the benefits of desalination extend beyond hydrogen production. The purified water created through this process can be utilized for essential community and agricultural purposes, such as providing clean drinking water or supporting farmers during droughts.

Pure Water for Drinking and Agriculture

Drinking Water:

- The desalination process produces high-quality, purified water. This water, after minimal additional treatment, can be directed into drinking water supplies, alleviating water scarcity issues in arid or drought-prone regions.

- Coastal communities, where access to fresh water is often limited, could benefit significantly from integrating desalination facilities into local water systems.

Agricultural Support:

- Fresh water from desalination can be diverted to support irrigation systems, helping farmers sustain crops during dry seasons or in areas with naturally saline groundwater.

- With agriculture being heavily impacted by climate change, desalinated water offers a reliable resource for maintaining food production and supporting livestock.

Integration with Hydrogen Production

By co-locating desalination plants with PEM hydrogen production facilities:

- Shared Resources: The fresh water generated can serve dual purposes, powering the electrolyzers for hydrogen production while also being allocated to drinking water supplies and farming needs.

- Efficient Use of Infrastructure: Shared pipelines and storage systems reduce costs, making the desalination process more economically viable.

- Environmental Benefits: Reusing the desalinated water for multiple purposes minimizes waste, ensuring a sustainable approach to managing both water and energy resources.

Addressing Water Scarcity with Hydrogen Technology

In areas facing critical water shortages, the integration of desalination and PEM technology presents a game-changing opportunity. As nations push toward hydrogen as a clean energy carrier, the parallel benefit of increasing freshwater availability could improve millions of lives:

- Improved Livelihoods: Farmers would have access to reliable water sources, reducing dependency on unpredictable rainfall.

- Enhanced Resilience: Communities would be better equipped to handle water crises caused by climate change, ensuring access to safe drinking water even in the driest conditions.

Investing in desalination not only supports clean energy initiatives but also strengthens water security, creating a win-win scenario for sustainable development and community well-being.

Green Hydrogen - is the perfect Energy future for the Planet.

Hydrogen Production and Transportation: Market Potential and Environmental Benefits

Hydrogen Production:

Hydrogen, a versatile and clean energy carrier, can be produced using various methods, each with distinct environmental impacts:

Electrolysis of Water:

- Description: Electrolysis uses electricity to split water into hydrogen and oxygen. When powered by renewable sources like solar, wind, or hydropower, it produces green hydrogen with zero carbon emissions.

- Advantages: Green hydrogen is a sustainable option with no direct CO2 emissions, making it ideal for a carbon-free energy future.

Steam Methane Reforming (SMR) with Carbon Capture:

- Description: SMR is the most common method for producing hydrogen, using natural gas as a feedstock. When combined with carbon capture and storage (CCS), it can reduce emissions significantly, creating what is known as blue hydrogen.

- Advantages: Blue hydrogen offers a transitional solution that leverages existing natural gas infrastructure while minimizing environmental impact.

Biomass Gasification:

- Description: Hydrogen can be produced by gasifying organic material from plants and waste. This process is carbon-neutral if managed sustainably.

- Advantages: It provides a renewable source of hydrogen and utilizes waste materials, enhancing overall resource efficiency.

Transportation of Hydrogen:

Hydrogen can be transported in various forms—compressed gas, liquid hydrogen, or chemically bonded in carriers such as ammonia or liquid organic hydrogen carriers (LOHCs). The choice of transport depends on the distance, infrastructure, and end-use requirements.

Pipelines:

- Description: Pipelines are the most efficient and cost-effective method for transporting hydrogen over long distances. Existing natural gas pipelines can often be repurposed or adapted for hydrogen, reducing initial investment costs.

- Advantages: Pipelines offer continuous supply and are ideal for connecting large-scale hydrogen production sites to industrial consumers or export terminals.

- Environmental Potential: Pipelines minimize transportation emissions compared to other methods, making them the most sustainable option for large volumes.

Shipping:

- Description: Hydrogen can be liquefied or converted into ammonia for maritime transport, allowing it to be shipped globally. This method is suitable for exporting hydrogen from countries with abundant renewable resources to those with high energy demand.

- Advantages: Shipping hydrogen opens global trade routes, enabling countries with renewable energy surpluses to export clean energy.

- Environmental Potential: While energy-intensive, technological advancements are reducing the carbon footprint of hydrogen shipping, especially when paired with green ammonia as a carrier.

E-Trucks and Rail:

- Description: Compressed hydrogen gas or liquid hydrogen can be transported via specially designed e-trucks or rail tankers. This method is effective for regional distribution from production hubs to local users.

- Advantages: Flexibility and adaptability make this mode suitable for connecting smaller or remote hydrogen production sites with end-users without the need for extensive pipeline infrastructure.

- Environmental Potential: E-trucks powered by hydrogen fuel cells or batteries further reduce the carbon impact of transportation.

Market Potential:

Hydrogen is poised to play a critical role in the global energy transition, with potential applications across multiple industries:

- Energy Sector: Hydrogen can be used in power generation, providing a clean, dispatchable energy source to balance intermittent renewables like wind and solar.

- Industrial Applications: Hydrogen is essential for decarbonizing hard-to-abate sectors such as steel, cement, and chemical manufacturing, where it can replace fossil fuels.

- Transport: Hydrogen-powered fuel cells offer a clean alternative for heavy-duty vehicles, shipping, and aviation, where batteries may be less practical due to weight and range limitations.

- Residential and Commercial Heating: Hydrogen can be blended with natural gas or used alone to provide low-emission heating solutions for homes and businesses.

Environmental Potential:

- Zero Emissions: When produced using renewable energy, hydrogen releases no greenhouse gases at the point of use, significantly reducing the carbon footprint of energy-intensive industries.

- Energy Storage: Hydrogen acts as a long-term energy storage solution, stabilizing grids with high penetration of renewables by storing excess energy during periods of low demand.

- Resource Efficiency: By utilizing water, biomass, or waste, hydrogen production can contribute to a circular economy, enhancing overall resource efficiency and reducing reliance on finite fossil fuels.

Conclusion:

Hydrogen presents a significant opportunity to drive global decarbonization, offering both market and environmental benefits. With the right infrastructure investments—such as pipelines, shipping routes, and advanced production facilities—hydrogen can become a cornerstone of a sustainable, low-carbon energy future. The potential to export clean hydrogen to energy-hungry markets further positions it as a key player in the global shift toward renewable energy.

Siemens' Role in Scaling Hydrogen Production

Siemens is uniquely positioned to drive the scaling of hydrogen production, leveraging its extensive expertise in advanced engineering, digitalization, and energy solutions.

As a global leader in sustainable technologies, Siemens plays a pivotal role in accelerating the hydrogen economy, which is crucial for decarbonizing industries, energy systems, and transport sectors.

Here’s how Siemens can help scale hydrogen production:

1. Advanced Electrolysis Technology for Green Hydrogen

- PEM Electrolysers: Siemens has developed Proton Exchange Membrane (PEM) electrolysers, such as the Siemens Silyzer series, which are among the most advanced technologies for producing green hydrogen. These electrolysers use renewable electricity to split water into hydrogen and oxygen, resulting in zero-emission hydrogen production.

- High Efficiency and Flexibility: Siemens’ electrolysers are designed for high efficiency and operational flexibility, allowing them to adapt quickly to varying renewable energy inputs from wind or solar power. This adaptability is crucial for integrating hydrogen production with fluctuating renewable sources.

- Scalability: Siemens’ modular electrolyser systems can be easily scaled up to meet growing hydrogen demand. From small-scale industrial applications to large-scale hydrogen production facilities, Siemens’ technology can expand capacity quickly and efficiently.

2. Digitalization and Optimization of Hydrogen Production

- Digital Twin Technology: Siemens uses digital twin technology to create virtual replicas of hydrogen production facilities, allowing for real-time monitoring, simulation, and optimization of the entire production process. This technology helps identify inefficiencies, predict maintenance needs, and optimize performance, reducing operational costs and downtime.

- AI and Machine Learning Integration: Siemens integrates AI and machine learning into its hydrogen production systems to optimize energy consumption, predict equipment wear, and automate decision-making processes. These technologies enhance the efficiency and reliability of hydrogen production plants.

- Smart Energy Management: Siemens provides smart energy management solutions that optimize the interaction between renewable energy sources and hydrogen production. By managing energy flows intelligently, Siemens ensures that hydrogen production is maximized when renewable power is abundant, reducing overall costs.

3. Hydrogen Infrastructure and Integration

- Hydrogen Storage and Distribution Solutions: Siemens not only focuses on production but also on the storage and distribution of hydrogen. Advanced storage solutions, including high-pressure tanks and innovative hydrogen carriers, enable safe and efficient hydrogen transport, supporting a stable supply chain.

- Grid Integration: Siemens’ expertise in smart grids and energy management allows seamless integration of hydrogen production into the existing energy infrastructure. This integration helps stabilize grids with high renewable penetration by using excess renewable energy for hydrogen production, effectively storing it for later use.

- Electrolyser-to-End-User Solutions: Siemens offers comprehensive solutions that connect hydrogen production to end-users, whether it’s for industrial processes, transportation, or power generation. This approach ensures a complete hydrogen ecosystem that is efficient, reliable, and scalable.

4. Supporting Decarbonization of Industry and Heavy Transport

- Industrial Decarbonization: Siemens provides hydrogen solutions tailored to industries such as steelmaking, chemicals, and refineries, which are traditionally hard to decarbonize. Hydrogen can replace fossil fuels in these sectors, significantly reducing carbon emissions.

- Hydrogen-Powered Mobility: Siemens is also involved in developing hydrogen fuel cell technologies for transport, including rail, heavy-duty trucks, and shipping. By enabling clean mobility solutions, Siemens helps expand the hydrogen market and reduce emissions in the transport sector.

- Mobile Hydrogen Power Generation: Siemens’ mobile hydrogen turbines offer flexible power generation solutions, ideal for remote locations, backup power, or temporary installations. These turbines can use green hydrogen, ensuring zero-emission power generation that can be rapidly deployed when needed.

5. Strategic Partnerships and Collaborative Initiatives

- Global Collaborations: Siemens actively partners with governments, industry leaders, and research institutions to accelerate the hydrogen economy. Collaborations with other energy companies, infrastructure developers, and technology providers allow Siemens to combine expertise and resources to scale hydrogen production.

- Pilot Projects and Demonstrations: Siemens participates in numerous pilot projects worldwide to demonstrate the feasibility and scalability of hydrogen technologies. These projects help refine technologies, establish best practices, and build the business case for large-scale hydrogen deployment.

6. Financial and Technical Support for Scaling Up

- Investment in Hydrogen Projects: Siemens invests in hydrogen projects through partnerships and funding, providing both financial and technical support to expand hydrogen infrastructure. This backing helps de-risk projects and attract additional investments.

- Training and Workforce Development: Siemens offers training and workforce development programs to build the skills needed for the growing hydrogen industry. By developing expertise in hydrogen technologies, Siemens ensures that there is a skilled workforce ready to support the scale-up of hydrogen production.

Conclusion

Siemens plays a critical role in scaling hydrogen production through advanced electrolyser technology, digital optimization, strategic partnerships, and integrated infrastructure solutions. By leveraging its extensive experience in energy, automation, and digitalization, Siemens is helping to make hydrogen a cornerstone of the global energy transition. As the demand for clean, sustainable energy continues to grow, Siemens’ commitment to advancing hydrogen technology will be instrumental in achieving a low-carbon future.

***