GRAPHENE-SILICON SOLAR CELLS

Graphene - Silicon Solar Cells efficiencies exceeding 30%

The efficiency of solar cells can be significantly impacted by the use of silicon and graphene compared to traditional materials. Silicon-based photovoltaic cells typically exhibit an energy conversion efficiency of around 18%.

On the other hand, graphene-based solar cells have shown the potential to achieve energy conversion efficiencies above 20%, with combined silicon-graphene cells reaching efficiencies exceeding 30%.

Incorporating graphene into solar cells has been found to improve electrical performance, with graphene-based electrodes showing enhanced conductance values and increased device efficiency by around 1.6%. Additionally, the integration of graphene with silicon in Schottky junctions for solar cell applications has garnered considerable interest, with strategies such as texturing the silicon substrate and using antireflection coatings being explored to further enhance efficiency.

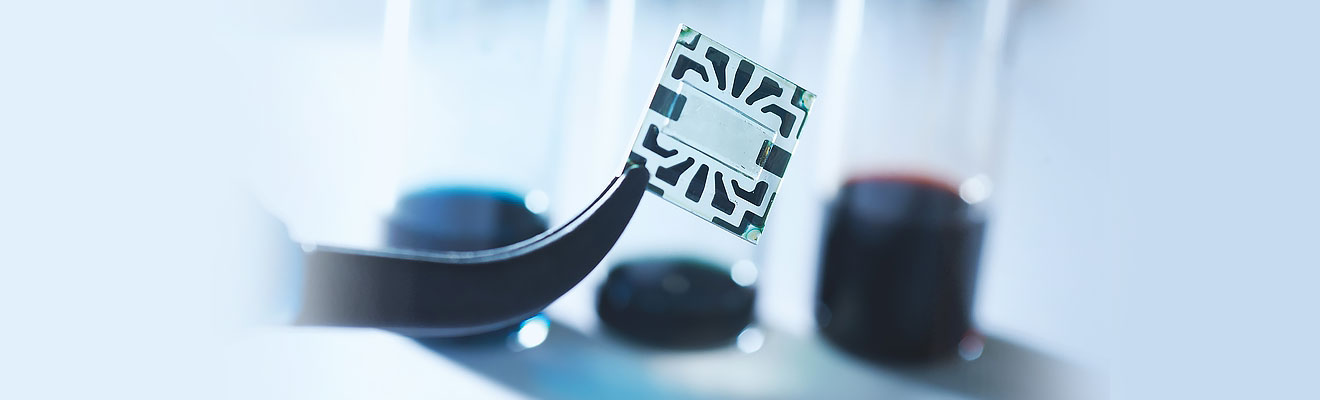

Photovoltaic solar cells made of organic compounds would offer a variety of advantages over today’s inorganic silicon solar cells. They would be cheaper and easier to manufacture. They would be lightweight and flexible rather than heavy, rigid, and fragile, and so would be easier to transport, including to remote regions with no central power grid. And they could be transparent. Many organic materials absorb the ultraviolet and infrared components of sunlight but transmit the visible part that our eyes can detect. Organic solar cells could therefore be mounted on surfaces all around us and harvest energy without our noticing them.

Researchers have made significant advances over the past decade toward developing transparent organic solar cells. But they’ve encountered one persistent stumbling block: finding suitable materials for the electrodes that carry current out of the cell.

What is solar panel efficiency?

A solar panel's efficiency measures its ability to convert sunlight into usable electricity. If the sun shines on a solar panel with a 20% efficiency rating, 20% of the sun's energy will convert to solar energy in ideal conditions. Given the same amount of sunlight shining simultaneously on two equal-sized solar panels with different efficiency ratings, the more efficient panel will produce more power than the less efficient panel.

Solar panels are made of up multiple silicon solar cells, which, combined, determine a panel's overall efficiency rating. The structure and type of silicon crystal (generally monocrystalline or polycrystalline), electrical configuration, and surrounding components of the solar cells all influence that number.

SKELETON is the global technology leader in producing high-power Curved Graphene Supercapacitor Cells, Super batteries to complete large scale Energy storage systems.

Their patented Curved Graphene carbon materials could provide efficiency increases towards Solar Cell technology. Skeleton has built Europe's largest Graphene supercapacitor production facility in Berlin - Germany and the most reputable multinational companies are knocking on their door.

IMAGINE - instantly, and safely charging your EV Battery by employing a Curved Graphene Super Battery. Instantly charging your mobile Phone. Existing Curved Graphene Technologies can be pivotal for GS Solar Cell developments.

Graphene-Silicon Solar Cell production in Australia is feasible

The feasibility of producing graphene-silicon solar cell panels in Australia depends on various factors, including technological readiness, economic considerations, availability of raw materials, infrastructure, and market demand. Here’s a detailed analysis of the key factors involved:

1. Technological Readiness

Graphene-Silicon Solar Cells:

- Current Research: Graphene-silicon solar cells are an emerging technology, combining the high electrical conductivity and transparency of graphene with the established photovoltaic properties of silicon. Research shows that graphene can enhance the efficiency and durability of silicon-based solar cells, potentially leading to higher efficiency solar panels.

- Development Stage: While there have been promising results in laboratory settings, graphene-silicon solar cells are still largely in the research and development (R&D) phase. Scaling up to commercial production requires overcoming challenges such as ensuring consistent quality, efficient large-scale manufacturing, and long-term stability.

Australia’s Technological Capabilities:

- Research Institutions: Australia has a strong research base in both graphene and solar technologies, with leading institutions like the Australian National University (ANU) and the University of Sydney conducting advanced research in these fields.

- Innovation Support: The Australian government has been supportive of renewable energy technologies, providing funding and incentives for innovation, which could facilitate the development of graphene-silicon solar cells.

2. Economic Considerations

Production Costs:

- Graphene Production: The cost of producing high-quality graphene is currently high, though ongoing advancements in production methods (like chemical vapor deposition and electrochemical exfoliation) are gradually reducing these costs.

- Silicon Integration: Integrating graphene with silicon in solar cells will add to manufacturing costs. However, the potential increase in efficiency could offset these costs over time by reducing the levelized cost of electricity (LCOE) from the solar panels.

Market Demand:

- Growing Solar Market: Australia has one of the highest per capita rates of solar panel installations in the world, driven by high solar irradiance and supportive government policies. The market demand for more efficient and durable solar panels is strong.

- Cost-Competitiveness: To be feasible, graphene-silicon solar panels must be cost-competitive with existing silicon-only solar panels. While the initial costs might be higher, the potential for higher efficiency and longer lifespan could appeal to both residential and commercial markets.

3. Availability of Raw Materials

Graphite for Graphene:

- Abundant Resources: Australia has significant graphite reserves, particularly in Western Australia, which can be used as the raw material for graphene production. This local availability reduces reliance on imports and supports a domestic supply chain.

Silicon:

- Established Industry: Australia is already involved in the global silicon supply chain, with raw materials like silica being readily available. The integration of graphene with silicon is feasible given the existing infrastructure.

4. Infrastructure and Manufacturing Capacity

Existing Manufacturing Infrastructure:

- Solar Panel Manufacturing: Australia has some solar panel manufacturing capabilities, though much of the production has shifted overseas. Reviving or expanding this capacity to accommodate graphene-silicon technology would require investment in new machinery and processes.

- Graphene Production Facilities: Currently, Australia has limited large-scale graphene production facilities. Developing this infrastructure is essential to support graphene-silicon solar panel production.

Required Investments:

- Capital Investment: Significant capital investment would be required to establish or upgrade manufacturing facilities for producing graphene-silicon solar cells. This includes investment in R&D, pilot plants, and full-scale production lines.

- Government Support: Government incentives, grants, and subsidies would be crucial to offset initial costs and encourage private sector investment in this new technology.

5. Environmental and Regulatory Considerations

Environmental Impact:

- Sustainability: Producing graphene-silicon solar panels in Australia could contribute to the country’s renewable energy goals. However, the environmental impact of graphene production, particularly in terms of energy use and chemical waste, must be managed carefully.

- Regulatory Compliance: The production process must comply with Australian environmental regulations, including waste management and emissions standards.

6. Market and Export Potential

Domestic Market:

- High Solar Adoption: With a high rate of solar adoption, the domestic market could provide a strong initial customer base for graphene-silicon solar panels. Government incentives for renewable energy could further boost this market.

- Grid Integration: Improved efficiency from graphene-silicon panels could help with the integration of solar energy into the grid, particularly in regions with high solar penetration.

Export Opportunities:

- Asia-Pacific Market: Proximity to major markets in the Asia-Pacific region, including China, Japan, and Southeast Asia, could provide export opportunities for Australian-produced graphene-silicon solar panels.

- Global Leadership: If Australia can successfully commercialize this technology, it could position itself as a leader in the next generation of solar technologies.

Conclusion

Feasibility:

- Moderately Feasible: While there are significant challenges to overcome, including the need for technological advancement, infrastructure development, and cost reduction, the potential benefits of producing graphene-silicon solar panels in Australia are substantial. The country’s strong research base, abundant raw materials, and existing solar market provide a solid foundation for developing this technology.

Next Steps:

- Focused R&D: Continued research and development are crucial to overcome current technical challenges and reduce production costs.

- Pilot Projects: Establishing pilot production facilities to test the scalability and economic viability of graphene-silicon solar panels.

- Government and Private Sector Collaboration: Partnerships between government, research institutions, and the private sector will be essential to drive innovation and investment in this emerging field.

If these challenges can be addressed, graphene-silicon solar panels could play a significant role in Australia’s renewable energy future, offering a more efficient and durable alternative to traditional solar technologies.